abaqus analysis projects

hi Abaqus students.

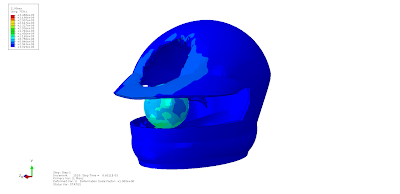

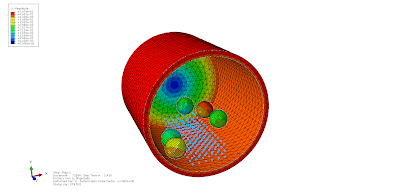

abaqus helmet impact test

In this post, we will look at the helmet impact test done on Abaqus software. Helmet to help save our lives in accidents when we are riding a motorcycle We do not know to what extent quality is produced. A helmet manufacturing company should focus more on its quality rather than on its design. The helmet thus made must also be lightweight. Thus the material used to make the helmet should be the right choice. In Abaqus software, you can test the extent of damage to the helmet when an object coming at high speed collides with the helmet. It is possible to create a high-quality helmet by publishing research articles like this.

You have to wait 180 seconds.

You have to wait 180 seconds.

You have to wait 180 seconds.

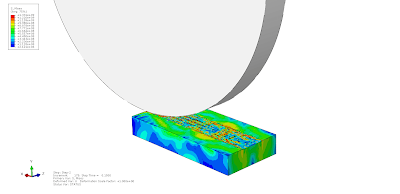

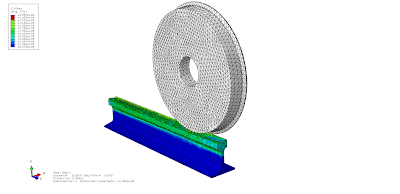

abaqus surface grinding

We will learn about the surface grinding process in this part. In this method, the coarse unwanted material on the surface of the workpiece is removed and a very smooth surface is created. In this method, the surface of the workpiece, which is firmly attached to the bed on a grinding wheel that rotates steadily on one side, is moved in the opposite direction to the grinding wheel at right intervals. This will significantly remove the surface of the workpiece. By repeating this process by moving the workpiece at significant intervals and removing the unwanted part of the workpiece surface, we get a smooth surface. You can also use this method to sharpen blunt tooltip. The abrasives particles are used as the cutting edge of the grinding wheel.This can be tested dynamic explicit in Abaqus software.

pay 10 Rs for surface grinding material properties file download click here

pay 100 Rs for surface grinding cae file download click here

Conditions:

1)Please avoid phone download, Please make this payment process on the computer.

2)Don't close the pc browser tab during this process.do wait for the entire process including download.

3)Don't forget to click the DONE button in after payment process.It will help you with file download.

4)This Cae file does not open in the Abaqus student version.

5)This Cae file does not open in the below Abaqus version 6.14.2.

pay 100 Rs for surface grinding step by step tutorial video click here

abaqus rotary friction welding

We will see what is rotary friction welding in this part. In this method, the two cylindrical metal rod must be rotated in opposite directions at high speed. Thus the rods rotating in the opposite direction should collide slowly under very high pressure. Thus heat is generated due to friction by rubbing against each other. This heat causes the friction ends of the rod to melt and bind between the two rods. It is noteworthy that in this method only cylindrical metals can be bonded. This can be done using Abaqus software to calculate the temperature difference at different rotational speeds. Let's also test how the bonding between different metals is.

pay 100 Rs for rfw cae file download click here

Conditions:

1)Please avoid phone download, Please make this payment process on the computer.

2)Don't close the pc browser tab during this process.do wait for the entire process including download.

3)Don't forget to click the DONE button in after payment process.It will help you with file download.

4)This Cae file does not open in the Abaqus student version.

5)This Cae file does not open in the below Abaqus version 6.14.2.

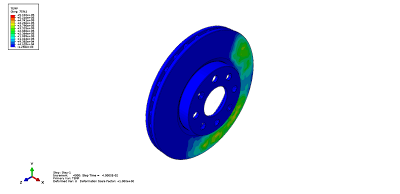

abaqus disk brake test

In this part, we can see the heat change in the disk brake caused by the friction while holding the brake while riding a two wheeler. In Abaqus software, you can calculate the thermal effect of a pad rubbing abruptly on a disk that is spinning very fast. This uses detect easily damaged material that can produce as little heat as is suitable for the disk brake. This will extend the life of the disk brake. We can test this phenomenon in Abaqus software with coupled temperature displacement or dynamic temperature displacement explicit in a very short period of time.

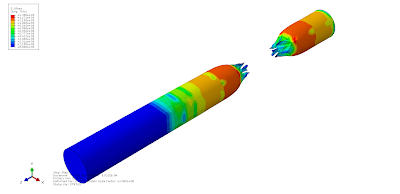

abaqus chip formation

We will learn some things about chip formation in this part. Usually, chip formation is an unwanted part of the workpiece that is removed by the lathe or CNC operation. This means that by moving the sharp edge of the tool slowly over the surface of the fast-rotating workpiece, the unwanted part of the workpiece is removed as a chip.By testing this method in Abaqus software we can calculate the amount of stress and strain rate on the surface of the general workpiece of the operation. You can also change the operating speed of the tool and the shape of the tool. This makes for efficient production.I ended up doing this in a dynamic explicit method. I used johnson cook damage parameters and a very sophisticated mesh system to do this project.

pay 10 Rs for chip formation material properties file download click here

pay 10 Rs for chip formation cae file download click here

Conditions:

1)Please avoid phone download, Please make this payment process on the computer.

2)Don't close the pc browser tab during this process.do wait for the entire process including download.

3)Don't forget to click the DONE button in after payment process.It will help you with file download.

4)This Cae file does not open in the Abaqus student version.

5)This Cae file does not open in the below Abaqus version 6.14.2.

abaqus tensile test

In this section, we will look at tensile testing in Abaqus software. The tensile test is used to determine the maximum strength of a material. For example, an iron rod of a certain thickness is held tightly at both its ends and pulled in the opposite direction. Thus when the rod is pulled in the opposite direction at high pressure it will start to stretch at a certain pressure and this position is called the yield point.The rod thus stretched may break in two above a certain force,This condition is called ultimate tensile strength. universal testing machine This tensile test is performed. We can do this dynamic explicit method in Abaqus software.I did this using johnson cook damage parameters.

You have to wait 180 seconds.

You have to wait 180 seconds.

abaqus rail wheel and track interaction

Here you can see the changes in the relationship between the rail wheel and the track. This can be done by the dynamic explicit method using the properties of steel in Abaqus software.

pay 10 Rs for rail wheel and track material properties file download click here

pay 10 Rs for wheel cad (IGS) file download click here

pay 10 Rs for track cad (IGS) file download click here

pay 10 Rs for rail wheel and track interaction test cae file download click here

Conditions:

1)Please avoid phone download, Please make this payment process on the computer.

2)Don't close the pc browser tab during this process.do wait for the entire process including download.

3)Don't forget to click the DONE button in after payment process.It will help you with file download.

4)This Cae file does not open in the Abaqus student version.

5)This Cae file does not open in the below Abaqus version 6.14.2.

abaqus drill

The chip formation that occurs during the drilling operation can be done dynamic explicit method in Abaqus software.

pay 10 Rs for drilling material properties file download click here

pay 50 Rs for drill bit cad (IGS) file download click here

pay 50 Rs for drilling cae file download click here

Conditions:

1)Please avoid phone download, Please make this payment process on the computer.

2)Don't close the pc browser tab during this process.do wait for the entire process including download.

3)Don't forget to click the DONE button in after payment process.It will help you with file download.

4)This Cae file does not open in the Abaqus student version.

5)This Cae file does not open in the below Abaqus version 6.14.2.

pay 50 Rs for drilling step by step tutorial video click here

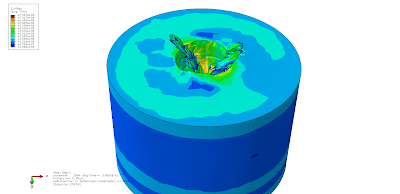

abaqus ball milling

ball milling is used to reduce the size of the material to a fine powder. for example, the waste material removed during the machining process is placed into a drum. And a certain number of hard steel balls are placed inside the drum. Now the drum will rotate at a certain speed. This causes the material inside the drum to collide with each other and turn into powder.

pay 10 Rs for ball milling material properties file download click here

pay 50 Rs for ball milling cae file download click here

Conditions:

1)Please avoid phone download, Please make this payment process on the computer.

2)Don't close the pc browser tab during this process.do wait for the entire process including download.

3)Don't forget to click the DONE button in after payment process.It will help you with file download.

4)This Cae file does not open in the Abaqus student version.

5)This Cae file does not open in the below Abaqus version 6.14.2.

car frame impact test

pay 500 Rs for car frame impact test cad (STEP) file download click here

pay 100 Rs for car frame impact test cae file download click here

Conditions:

1)Please avoid phone download, Please make this payment process on the computer.

2)Don't close the pc browser tab during this process.do wait for the entire process including download.

3)Don't forget to click the DONE button in after payment process.It will help you with file download.

4)This Cae file does not open in the Abaqus student version.

5)This Cae file does not open in the below Abaqus version 6.14.2.

click here for helmet impact test material properties

click here for cad file

click here for helmet impact test CAE file

click here for tensile test material properties

click here for tensile test cae file

Comments

Post a Comment

Thanks for visiting my blog